Innovation at Thai Summit

Partner with confidence

Thai Summit America continually pursues the most effective production methods derived from the latest technology. The use of innovative equipment and processes has been an important factor in our success. The following technologies are examples of new processes Thai Summit America Corporation has developed or is currently investigating:

- Non-Contact Measurement Systems

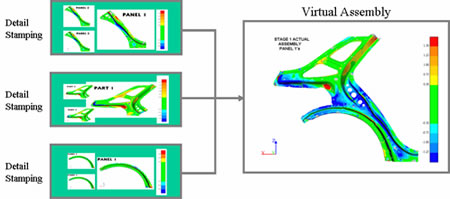

- Development of Virtual Builds

- Integration of Laser Welding in Production

- Extra Deep Draw Dies for Aluminum

- Tailor Welded Aluminum Stamping

- Electro-Magnetic Forming

- Die Floater Drawing Process

- Secondary Processing of Superformed Panels

- Nano-Polymer Technologies

- Roll Hemming Build Optimization

Integration of Laser Welding in Production

Integration of Laser Welding in Production Electro-Magnetic Forming

Electro-Magnetic Forming